Rusty Brains - RB001

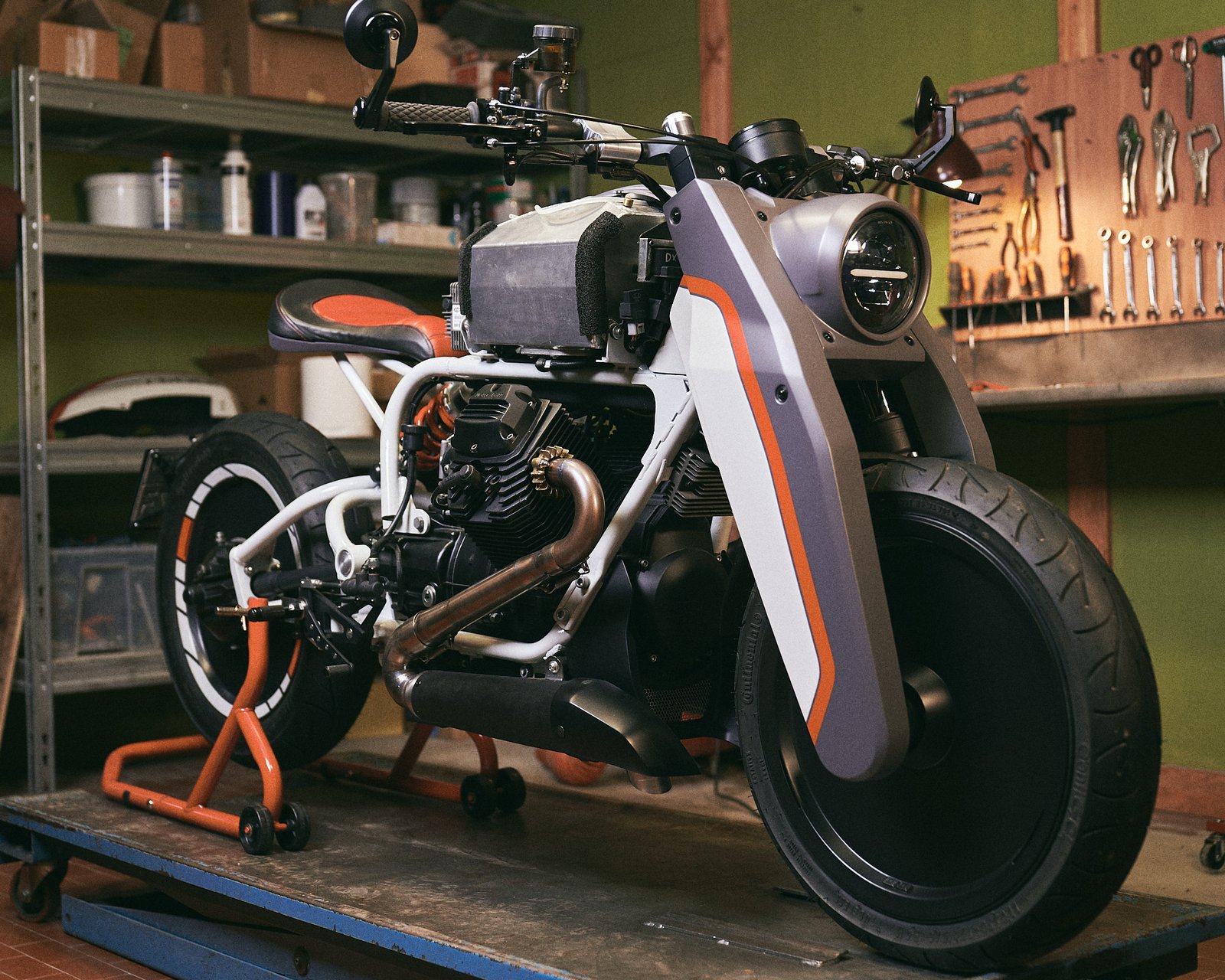

Rusty Brains is an idea born in 2019 by Luca Adami, Silvio Ferraretto and Bogdan Lupu: two style modelers in the business for 35 years and a photographer. The first project under this brand is the RB001.

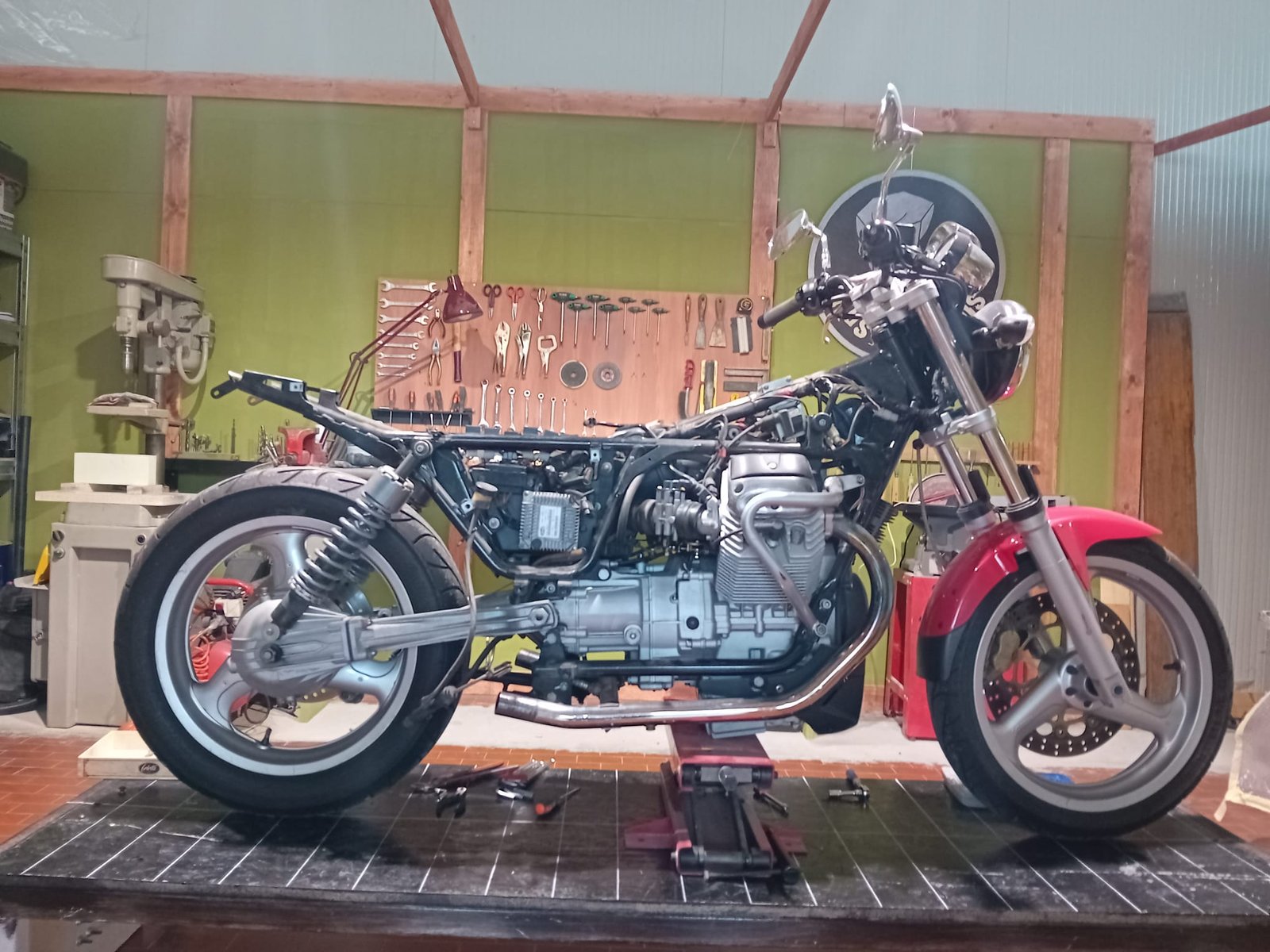

The base is a 2009 Moto Guzzi Breva 750ie which has been given a new aesthetic figure, the inspiration is the modified motorcycles of the 30s - 40s, therefore massive front end, characterizing tank, single-seater saddle, and completely naked rear wheel.

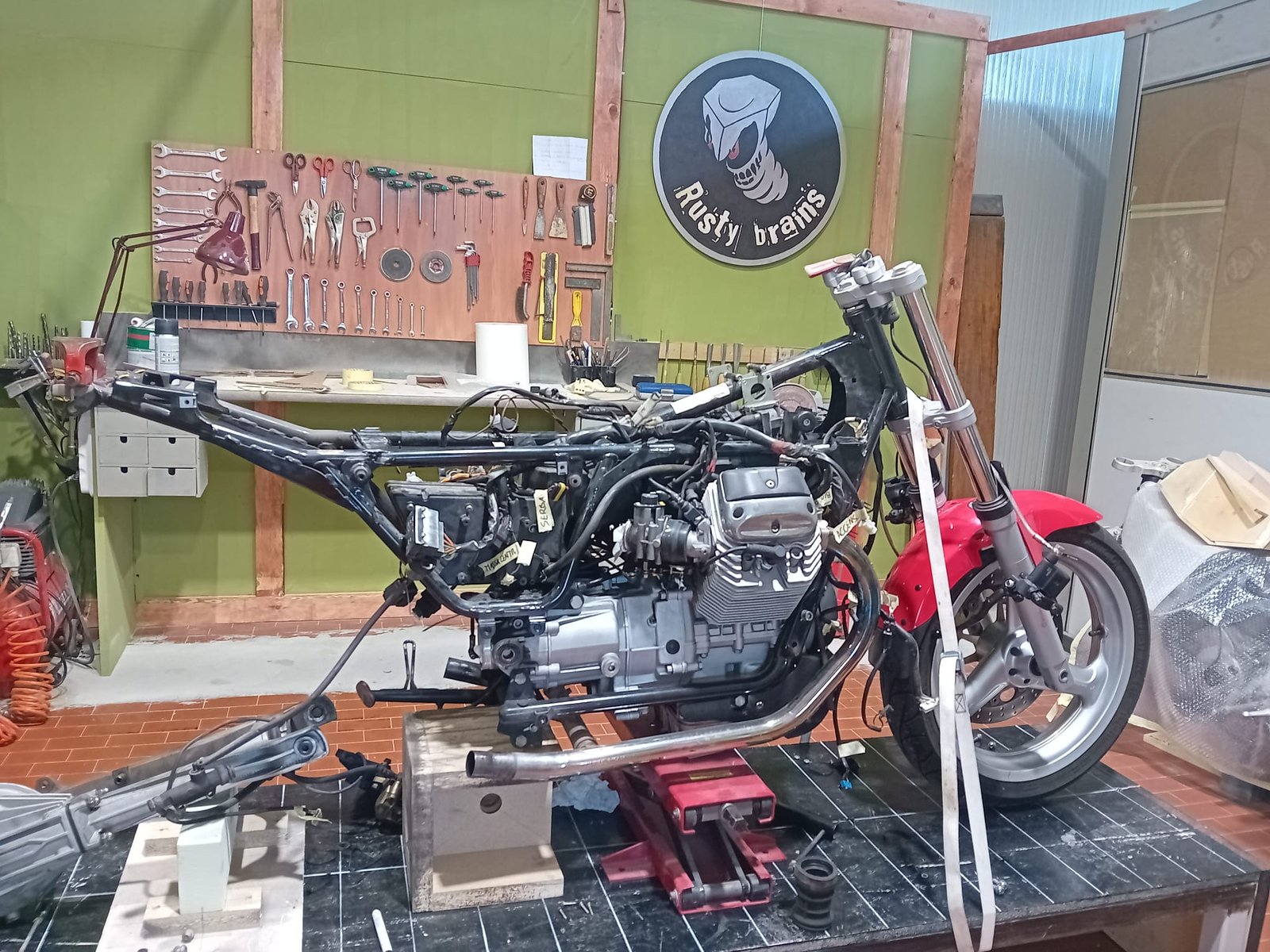

The aesthetics so radical compared to the original Guzzi project led to the modification of the frame and the redesign of the swingarm as well as many other technical parts.

The vehicle has been lengthened by 90mm, the stems pulled out by 30mm to give an aggressive and important appeal. All the bodies including the saddle have been modeled by hand, and the execution of the molds and glass resins is also manual. The steering plate, the frame modifications and the swingarm were designed in CAD, as were the footrests with the “reverse engineering” process.

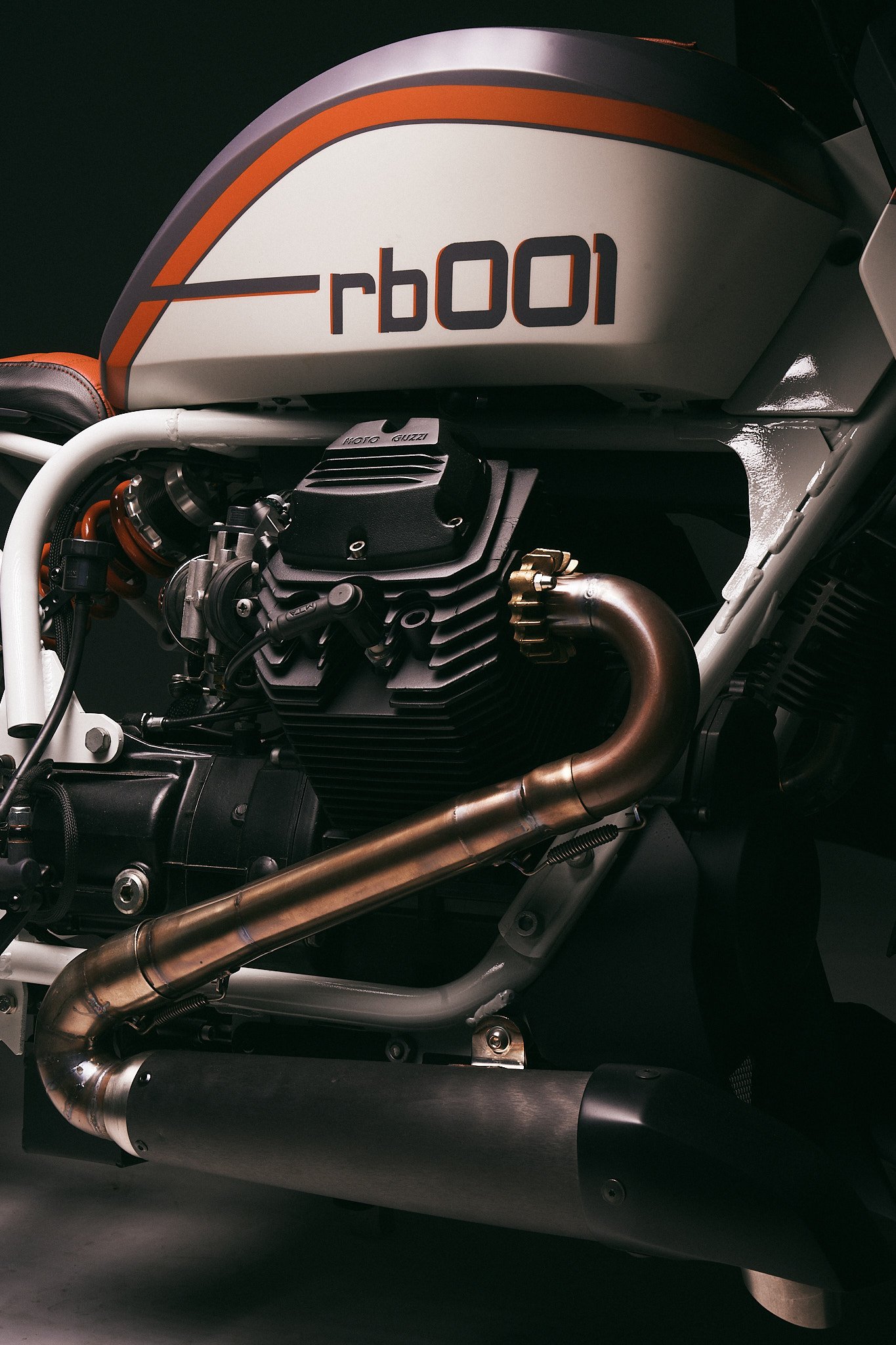

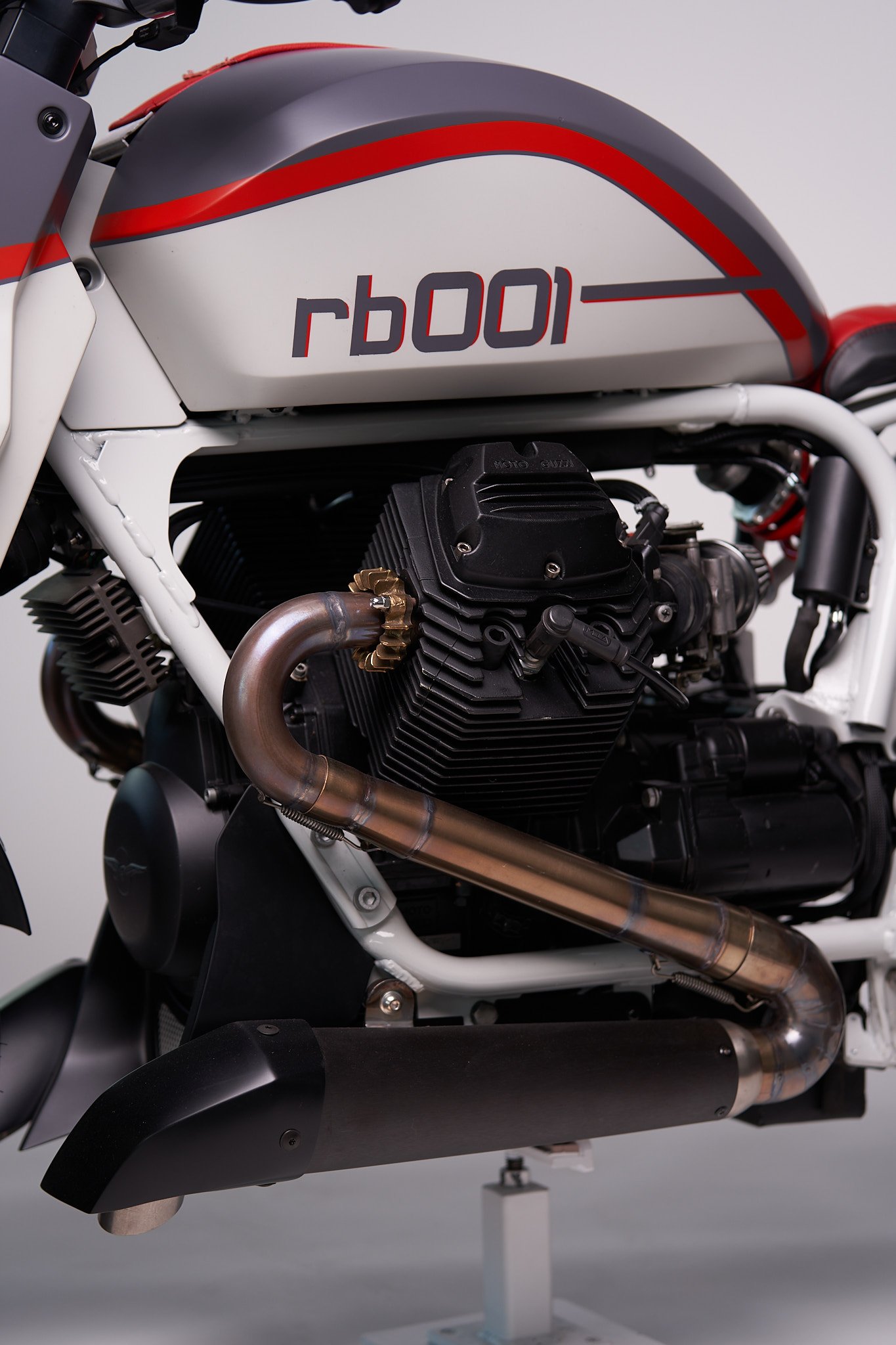

The frame and swingarm project was created in collaboration with Giuseppe Ghezzi. The exhaust so characterizing was designed and built by Rino Baldissin “Motorando”.

The graphics were designed by Andrea Giancristofaro.

The RB001 project wants to bring innovation to the world of customization, maintaining the performance of the original alley and enhancing the aesthetics by proposing a new archetype.

DESIGN AND BODYWORK

The allure of a classic triangular rigid frame, a slim single-seat saddle, and a quadrilateral front fork heavily influenced the sketch that gave birth to the RB001. It is not intended to be yet another vintage replica but rather draws inspiration from those forms to offer a timeless design projected into the future.

The evident forward weight distribution of the volumes is deliberate, aiming to convey dynamism and strength with a minimalist elegance despite its audacity. Taut surfaces, edges, faceted connections, and a cohesive whole distinguish it from the fragmented overemphasis of current styling trends.

On a technical base identical to the final version, all the RB001's bodywork elements were hand-sculpted. The molds, highly complex due to their shapes, were also manually crafted from the final models, as were the fiberglass layers derived from them. The under-seat structure and the foam of the seat, made of aeronautical material, were also modeled and molded by hand.

Compared to the original vehicle (Breva 750 ie), the RB001 features a 90mm extended wheelbase, creating a more imposing overall dimension and balancing the large volume of the faux fuel tank and the muscular front end. Wheel covers are stylistically necessary to align the original Breva wheels with the desired design, as these wheels would otherwise be unsuitable. Retaining the original wheels ensures aesthetic consistency through the covers and adheres to the mechanical constraints of the small Moto Guzzi series, which prevents the installation of a wider tire due to the driveshaft's interference with the tire's sidewall.

The tank, seat, front fork covers, headlight fairing, upper steering plate, and tailpiece form a cohesive unit conceived and modeled as a single sculpture.

FUEL TANK

The section identified as the tank is actually a two-part cover bolted together along the midline and to the frame via five fixed brackets. Inside, it houses not only the handmade Rusty Brains aluminum fuel tank but also all the components of the electrical system.

An old-style inspired feature is the leather central strap, which on the RB001, unlike its historical function, serves to "break up" the large tank volume and conceals the fuel filler cap opening and access to the repositioned original fuse box. The strap's width is a recurring stylistic element across all bodywork parts, including the diameter of the new instrument.

FRONT COVERS

A defining and provocative feature of the RB001 is the front suspension covers, which evoke strength and irreverent elegance. The shapes and facets of the surfaces, blending seamlessly with the tank, were designed to evoke these sensations. The technical challenge of allowing the fork tubes, brake caliper, and wheel to move within the covers, without interfering with the substantial volumes of the rest of the bodywork during steering, was resolved through precise cuts, volume adjustments, and Rusty Brains' design expertise.

HEADLIGHT COVER

The quality of craftsmanship is also evident in the modeling and construction of the headlight cover, which connects the two lateral fork covers with four screws.

A steel bracket, concealed under the fiberglass, supports the entire assembly and allows headlight adjustment. In this way, the headlight is not attached to the covers but more effectively secured to the steering plates.

STEERING PLATE

An integral part of the front styling is the upper steering plate, which connects the handlebar and instrument (round, traditional) to the bodywork volumes. The design evolved from an initial pen sketch to a rough CAD drawing, followed by a 3D-printed prototype mounted on the bike and refined by hand. After taking geometric measurements on a reference plane, the detailed project was finalized, creating a mathematical file necessary for CNC milling from solid aluminum.

LENTICULAR WHEEL COVERS

Using computer-aided design, the mold for the wheel covers was created. From a single 3D-printed matrix, specially designed and equipped, four fiberglass lenticular covers are produced and later adhered to the channels of the original wheels. These elements are engineered not to interfere with or be damaged during tire changes. They also feature openings for inflation valves and slits designed to drain any water that may infiltrate the internal cavity.

UNDER-SEAT COVER

The under-seat cover was shaped directly on the already leather-upholstered seat to ensure a perfect fit. Made from a manually crafted fiberglass mold, it conceals the lower part of the seat structure, hiding the retaining bracket and reinforcement ribs. A shallow recess houses the rear light, consisting of an LED strip that serves as a position light, brake light, and turn indicators.

TAILPIECE

The exhaust system, with its distinctly extreme and original design, terminates in a tailpiece comprising three fiberglass elements: two end caps for the silencers and an air intake that connects them under the alternator. For technical reasons, these three components are not mechanically linked but form a stylistically cohesive unit that accentuates the RB001’s aggressive character.

LICENSE PLATE HOLDER

The license plate holder frame, made of hand-bent C40 steel tubes, is another Rusty Brains creation. It is designed to conceal the license plate light connectors in the swingarm connection and to prevent vibrations or shaking during movement.

FRONT FENDER

A rear fender is not included, as it would contradict the RB001's styling. For the front wheel, however, there is a small fiberglass fender that integrates the fork brace and protects the engine casing. It does not extend forward to avoid disrupting the aesthetic profile of the fork covers, and its rear section bears the embossed Rusty Brains logo.

GRAPHICS

The RB001’s style is elevated and completed by the paint graphics, conceived as a unified design by Andrea "ND Design" Giancristofaro. Beyond the colors, which on this unit are Rusty Brains' official palette, the lines underscore the inspiration of the original sketch and highlight the frame architecture without visually breaking the volumes. In this way, the graphics become an integral part of the sculptural appearance of this highly original custom motorcycle.

RB001 TECHNICAL BASE

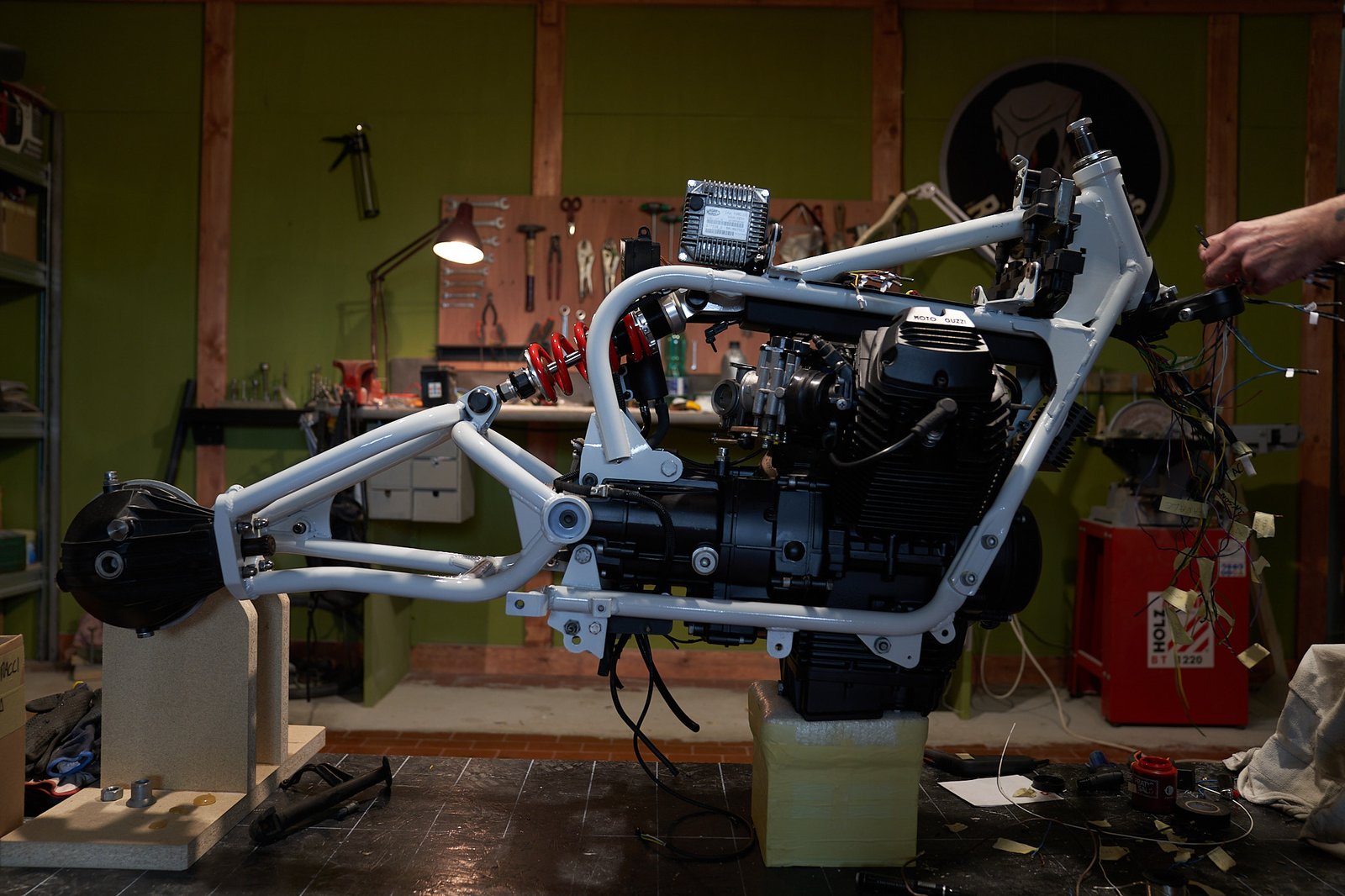

The essential feature of the overall appearance of the RB001 is the engine's parallel alignment to the road plane, which originally tilts downward at the rear. This inclination is structurally necessary for the manufacturer to align the gearbox output shaft with the crankshaft, given the high front end relative to the standard wheelbase.

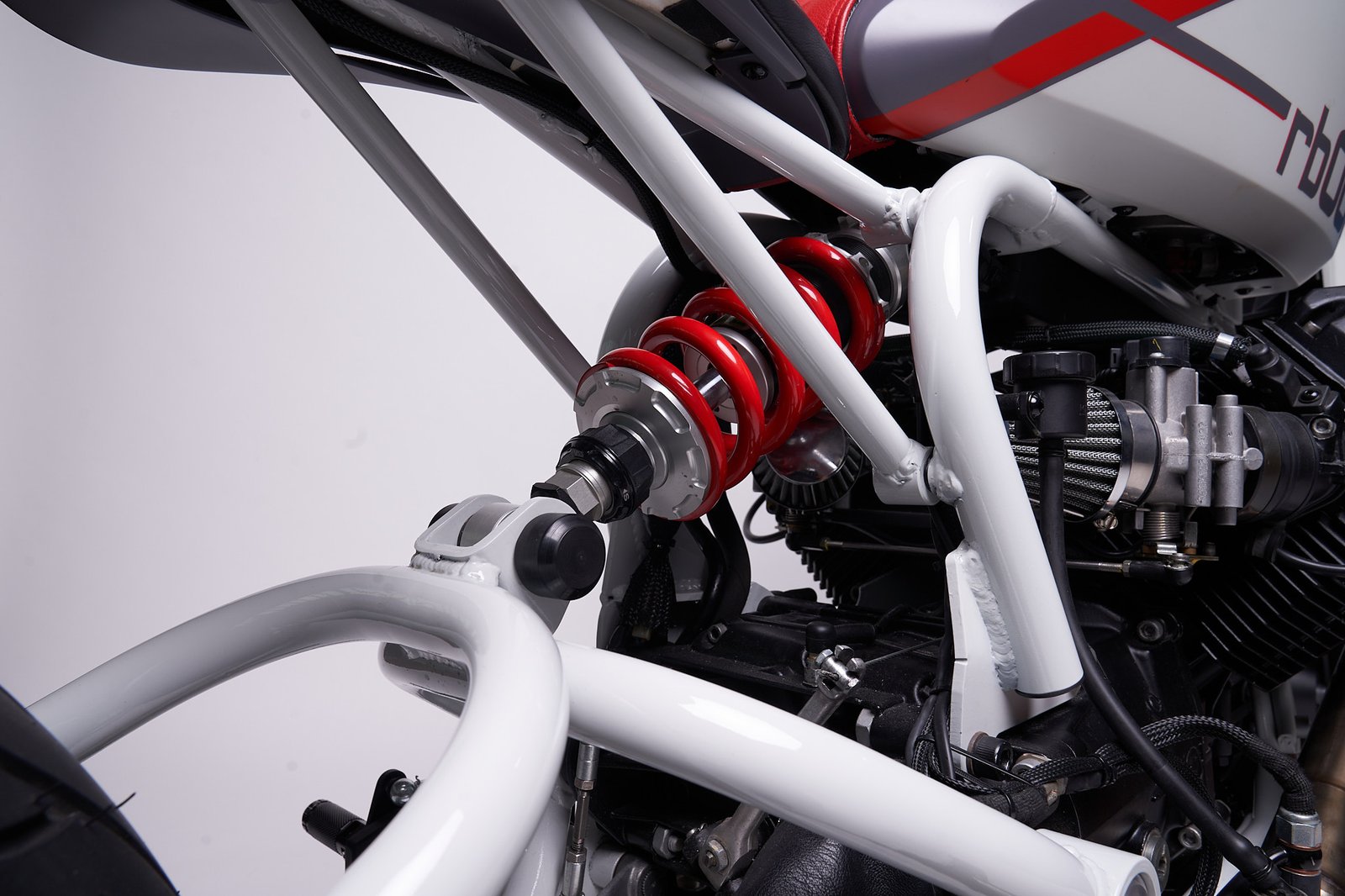

Another fundamental aspect of the RB001's aesthetics is the rear suspension. This component integrates the diagonal of the triangle forming the foundation of the chassis design for this custom build. This triangular figure consists of the engine aligned with the road plane, the steering headstock, and the wheel pivot, leaving space between the seat and the rear wheel. This gap becomes one of the stylistic hallmarks of the RB001.

Additionally, the original sketch envisions a vehicle with a significantly extended wheelbase compared to the original to proportion the volumes for the desired stylistic effect. The greater distance between the wheels, combined with other front-end adjustments, enhances stability without compromising agility in tight spaces and provides excellent control at both low and high speeds.

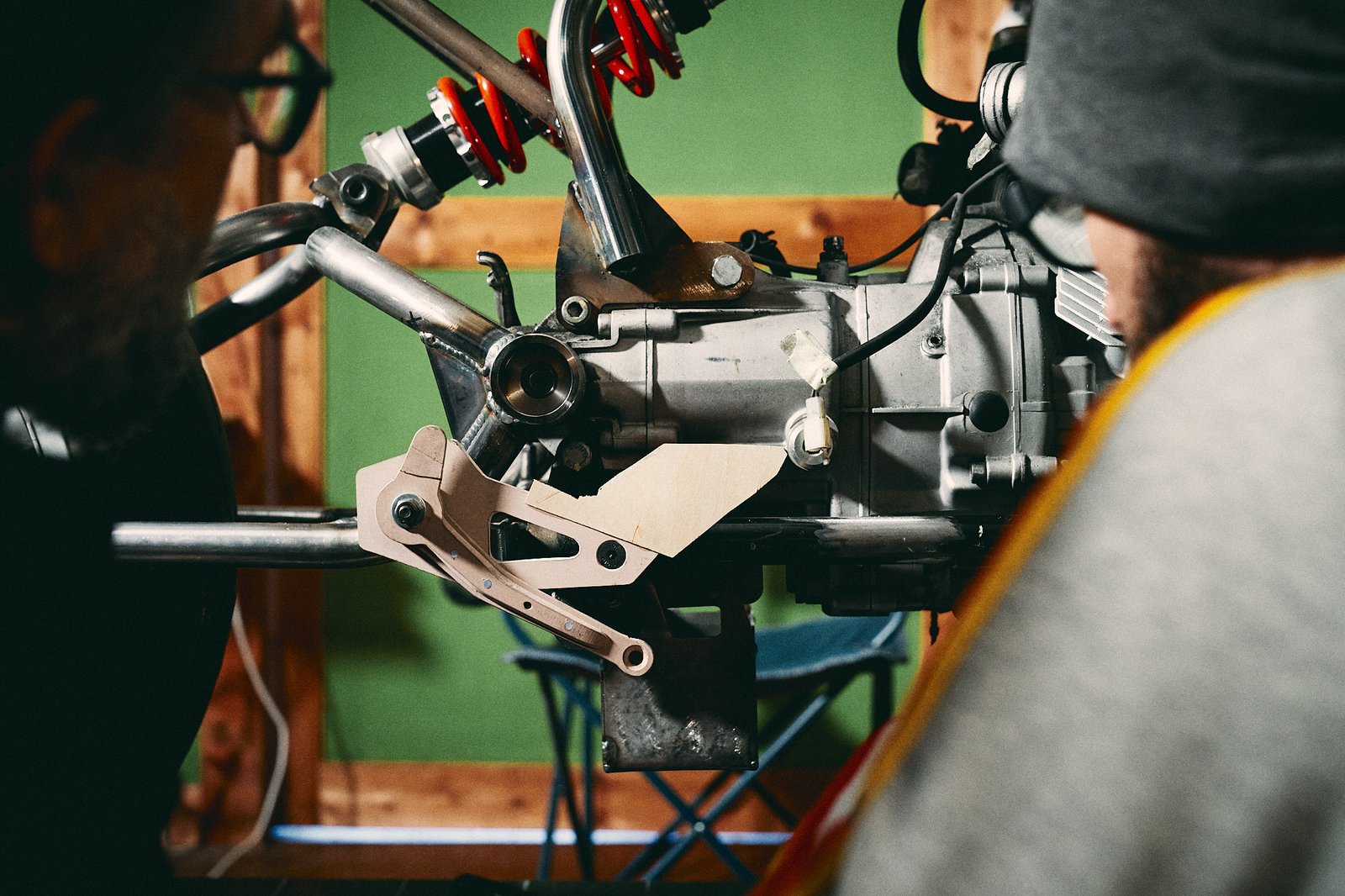

SWINGARM

The new swingarm design was achieved through reverse engineering. Following the positioning of the engine relative to the road plane and the final ground clearance, with the assembled frame and rear wheel mounted at a calculated midpoint, geometric measurements of the mounting points were taken in all three axes (x-y-z).

The cantilever swingarm was designed in-house at Rusty Brains using CAD and approved for mechanical and chassis functions by Giuseppe Ghezzi. The 3D model serves a dual purpose:

- Providing files for producing CNC-bent tubes, waterjet-cut brackets and plates, and machined bushings.

- Performing load calculations for the suspension.

The swingarm is made entirely of C40 steel with 28mm diameter tubes, continuously welded on a hand-made jig designed to avoid additional CNC processing after welding.

FRAME

Like the swingarm, new parts of the frame were also designed using CAD. The original "TONTI" frame was cut at the rear of the upper cross member, utilizing it and the steering head gusset as anchor points for the suspension brackets.

The removed section was replaced with two seemingly simple curved tubes that transfer stress to plates bolted to the gearbox/transmission area. This approach lightens the central portion of the vehicle stylistically, contributing to its minimalist yet solid and sleek appearance. The new sections, made of C40 steel tubes with a 28mm diameter, are sleeved and continuously welded, as are the engine mount plates and frame attachment bushings.

CAD-designed and CNC-machined in aluminum, the two pivot bolt locking stops for the swingarm were also created as aesthetic details.

BATTERY SUPPORT

Originally, the lower subframe halves, to which the footpeg brackets are welded, featured a cross member that in some configurations housed the central stand. This cross member was modified by adding a quick-release battery box system, also made of steel.

The battery, aesthetically concealed between the footpegs and under the transmission, despite its generous size, is positioned this way for functional and aesthetic reasons. A traditional vertically mounted battery was chosen for reliable vehicle operation. The new housing also shortens the power cable feeding the starter motor, enhancing start-up performance.

SEAT FRAME

The seat frame consists of 18mm diameter tubes, also made of C40 steel, and bolts to bushings welded internally to the new curved portions of the revised frame. The design is intended to make the rider appear as if suspended in mid-air, while the project incorporates triangulation that ensures extreme robustness.

FRONT END

From a technical perspective, the front end has not undergone radical replacements or modifications except for lowering the fork tubes and redesigning the lower steering plate. The fork tubes were lowered by 30mm for two primary reasons:

- Aesthetic: to align the engine parallel to the ground, emphasizing the bike's aggressive appeal.

- Functional: to maintain handling despite the 90mm wheelbase extension.

The new upper steering plate, designed in-house by Rusty Brains, features a minimalist design consistent with the style of other aesthetic components. CAD-designed and CNC-milled from duralumin, it includes mounts for the fork/headlight support bracket and, on the sides, two clamp hubs for the adjustable clip-ons. These clamps, another Rusty Brains project, consist of a simple connecting rod milled from solid aluminum, joining the steering plate to the handlebars while allowing the clip-ons to be adjusted 360 degrees relative to their base.

ELECTRICAL SYSTEM

Given the bike's unique and original design, the vehicle's technical base incorporates additional custom-made components. All electronic management elements and the actual fuel tank are enclosed within a fiberglass cover. Mounting brackets are welded onto the original frame section for securing silent-block mounts for the tank and brackets housing the relays, control unit, fuses, dual coils, and original tilt sensor.

Attached beneath the same frame section is a fiberglass tray that organizes the vehicle's electrical wiring (entirely redesigned and modified by Rusty Brains), oil vapor recovery hoses, and fuel lines. Concealing these elements creates a clean aesthetic above the engine, highlighting the throttle and clutch cables.

FUEL TANK

Using reverse engineering, a new 11-liter fuel tank was fabricated from 2mm-thick aluminum sheets. Laser-cut, CNC-bent, and TIG-welded by hand, it retains the original fuel pump while optimizing its functionality.

BLOB-HI (Oil Vapor Recovery System)

Special attention was given to designing and manufacturing the oil vapor recovery expansion tank, which collects vapors from the valve covers. The small cylindrical tank is positioned within the left frame curve, concealing the oil recovery and air exhaust hoses behind the gearbox mounting plate.

FORK/HEADLIGHT BRACKET

A steel fork/headlight bracket, also the result of reverse engineering, is mounted between the steering plates. It secures the front fork covers and anchors the adjustable LED headlight brackets, designed to ensure alignment within the surrounding fairing.

FOOT PEGS

The foot pegs were initially hand-prototyped in synthetic wood to achieve optimal ergonomics and design. After geometric measurements were taken on a reference plane, they were CAD-designed, waterjet-cut from aluminum plates of various thicknesses, and then hand-finished with files and abrasives.

EXHAUST SYSTEM

The RB001’s exhaust system was designed and built by Rino "motorando" Baldissin and represents the perfect fusion of technical expertise and creative genius. The system runs alongside the engine block, beneath the cylinders, entirely positioned ahead of the foot pegs—innovative and unique.

The bulky original airbox was proudly eliminated, replaced by two truncated-cone filters directly fitted onto the throttle body intakes. The new exhaust system features stainless steel headers with a compensator, brushed black Exan stainless steel silencers, and fiberglass-coated tailpipes crafted internally by Rusty Brains. The headers curve under the cylinders in a dual arc, with the silencers positioned wind-facing alongside the engine casing. Curved, "salami-slice" cut tailpipes direct gases downward, facilitating flow during motion. The variable-diameter tubing was calculated to optimize engine performance, compensating for the lack of the original airbox and the reduced size of the new intake filters.

Additionally, the exhaust provides the RB001 with an unexpectedly deep and aggressive sound without being unpleasant. Downstream of the dual arcs, beneath the gearbox, lies the compensator with the original lambda sensor mount, which is wrapped in a thermal-insulating fiber to shield the adjacent battery box from heat radiation.

MISCELLANEOUS

Technical components retained in their original form and reassembled on the vehicle include:

- The driveshaft

- Wheels and tire sizes

- Brake calipers with front and rear discs

- Rear brake reaction rod

- Front suspension with the lower steering plate

Rusty Brains - RB001

Rusty Brains is an idea born in 2019 by Luca Adami, Silvio Ferraretto and Bogdan Lupu: two style modelers in the business for 35 years and a photographer. The first project under this brand is the RB001.

The base is a 2009 Moto Guzzi Breva 750ie which has been given a new aesthetic figure, the inspiration is the modified motorcycles of the 30s - 40s, therefore massive front end, characterizing tank, single-seater saddle, and completely naked rear wheel.

The aesthetics so radical compared to the original Guzzi project led to the modification of the frame and the redesign of the swingarm as well as many other technical parts.

The vehicle has been lengthened by 90mm, the stems pulled out by 30mm to give an aggressive and important appeal. All the bodies including the saddle have been modeled by hand, and the execution of the molds and glass resins is also manual. The steering plate, the frame modifications and the swingarm were designed in CAD, as were the footrests with the “reverse engineering” process.

The frame and swingarm project was created in collaboration with Giuseppe Ghezzi. The exhaust so characterizing was designed and built by Rino Baldissin “Motorando”.

The graphics were designed by Andrea Giancristofaro.

The RB001 project wants to bring innovation to the world of customization, maintaining the performance of the original alley and enhancing the aesthetics by proposing a new archetype.